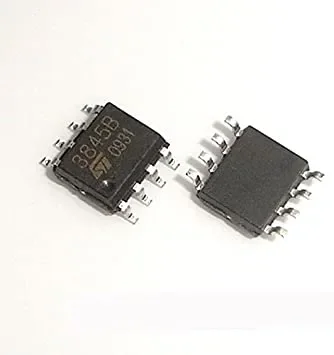

An SMD IC, or Surface-Mount Device Integrated Circuit, serves as a game-changer in the electronics industry as it facilitates the mass production of electronic devices that are both compact and powerful. SMD’s Integrated Circuit (IC) devices differ from the conventional components inserted using leads into drilled holes on the PCB (through-hole approach) in that SMD devices are soldered on the surface of the PCB. This method enhances the efficiency of the assembly process and increases the density of circuits, hence SMDs components are widely used in shrinking electronics.

Main Characteristics of SMD ICs

Lowers the Volume of Emission

SMD ICs are less in volume compared to through-hole components. The combination of surface mounting techniques and the absence of long leads minimizes the space, thus making it more suitable to create smaller and lighter-weight electronic devices.

Higher Circuit Density

SMD ICs are critical and need a higher degree of integration to achieve design objectives. This fact is important for the majority of applications such as SIM Cards in cell phones, the main circuits in computer laptops, and even wearables.

Parasites are Lowered

Parasitic inductance and capacitance are assets that are avoided in the manufacture and design of SMD ICs. This is because they have short leads as well as closely mounted components embedded into the PCB which creates a low parasitic inductance as well as capacitance thereby enhancing high-frequency performance

Reviews

There are no reviews yet.